X738

Ride-on Mowers

Features

19-kW (25.5-hp) engine

19-kW (25.5-hp) engine

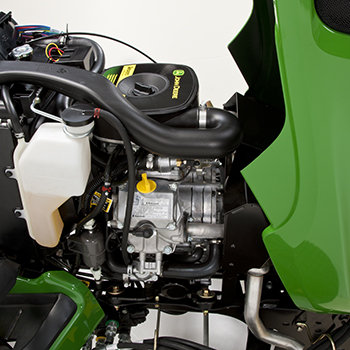

The V-twin, liquid-cooled John Deere iTorque power system with electronic fuel injection (EFI) provides exceptional performance and has the durability to handle commercial-use applications. The John Deere iTorque power system includes a combination of engine features that provide more lugging ability, even cooling, and durability.

iTorque stands for intelligent design (to get a task done efficiently) and torque (good lugging ability). It is used exclusively on gasoline-powered Select Series™ and Signature Series Tractors.

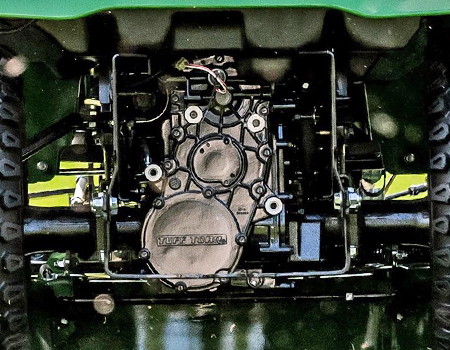

Hood opened to show engine

Hood opened to show engine

The 19-kW (25.5-hp) liquid-cooled V-twin engine has a large 745-cc (45.5-cu in.) displacement to provide plenty of power and torque for excellent performance in any operating condition. The one-piece hood is hinged to open for convenient engine service.

Key engine features include:

- Liquid cooling

- Longer engine life

- Quieter operation

- Improved fuel economy

- V-twin cylinder design

- Smoother running

- Easier starting

- Overhead valve (OHV) design to provide more efficient airflow for improved combustion

- More horsepower and torque per cubic inch of displacement

- Better cooling for longer engine life

- Reduced oil consumption

- Improved fuel economy

- Full-pressure lubrication with replaceable oil filter that provides plenty of clean oil for long engine life

- Horizontal crankshaft with a drive shaft connection to the transmission for positive power transfer

- Aluminum block and cast-iron cylinder liners

- Efficient heat dissipation

- Strength and durability with less weight

- Low exhaust emissions to meet U.S. Environmental Protection Agency (EPA) clean air standards

- Liquid cooling for consistent operating temperatures

- OHV for efficient lean burn combustion

- Precise air-to-fuel ratio control with electronic fuel injection

- Closed crankcase ventilation re-circulates and burns crankcase hydrocarbons

- Oil drain valve with hose and oil filter drip tray for easy, no-mess maintenance

- Electronic ignition for quick, sure starts

- Rubber engine mounts

- Vibration-free operation

- Lower noise

- Electric fuel pump ensures positive fuel delivery for fast starts and smooth running

- Solenoid-shift starter ensures that starter stays engaged until key switch is released for fast cold-weather starts

Battery and alternator are large capacity

Battery located at front of tractor frame

Battery located at front of tractor frame

A high-capacity regulated alternator charging system provides plenty of power to quickly recharge the battery and run electrical equipment, such as lights or a sprayer:

- 20-amp alternator is provided as standard equipment on gasoline engines.

- An optional 20-amp auxiliary alternator kit operates in parallel with the standard 20-amp engine-equipped alternator to bring the total of 12-V electric power to 40 amps.

A large-capacity, 300 cold-cranking amp battery provides plenty of cranking power for quick, sure starts in cold weather:

- Mounted at the front of the tractor frame for easy accessibility

Air intake system

Air intake screens on hood and pedestal

Air intake screens on hood and pedestal

Radiator screen pulled out for cleaning

Radiator screen pulled out for cleaning

Engine intake air is drawn in through screened panels at the base of the pedestal and on the right and left sides of the tractor hood:

- Cleanest and coolest area of the tractor

- Pre-cleans the air to keep large chaff and debris from entering the radiator or air cleaner

- Easy to clean and service so engine operates at optimum temperature

An inertia-discharge canister with dry-type paper element surrounded by a foam precleaner cleans intake air for long engine life:

- Ejects large dirt particles before they make contact with the filter

- Provides dual protection against dirt entering the engine

- Easily removed for cleaning or replacement

- Recommend the air filter be replaced and the precleaner cleaned annually or every 200 hours, whichever comes first

Electronic fuel injection

Electronic fuel injection (EFI) offers many important performance advantages:

- Immediate starting in hot or cold ambient temperatures or after long periods of seasonal storage

- No choke linkage for the user to operate

- No engine warmup required, so the implement can be engaged immediately after the engine starts

- Greater horsepower and torque responsiveness

- Higher reliability with the elimination of vapor locking, misfiring, run-on, and after-bang

- Automatic altitude compensation

- Delivers fuel precisely

- Reduces the potential for plug fouling

Fuel tank has a large 19.7-L (5.2-U.S. gal.) capacity

Fuel cap and tank (shown on X758 Diesel Tractor)

Fuel cap and tank (shown on X758 Diesel Tractor)

A large, 19.7-L (5.2-U.S. gal.) capacity fuel tank holds enough fuel for extended operation between refills:

- Fuel-fill location is on the left fender for easy access, increased safety, fewer spills, and convenience during filling.

- In-tank electric fuel pump supplies ample fuel flow to eliminate vapor lock and ensure quick engine starts, even after months of storage.

X739 Tractor mowing with 137-cm (54-in.) HC Mower Deck

X739 Tractor mowing with 137-cm (54-in.) HC Mower Deck

Side view of mower deck

Side view of mower deck

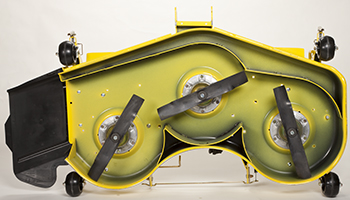

A deep-deck design of 14 cm (5.5 in.) delivers excellent airflow so material can be processed quickly and efficiently. The deck is stamped from 9-gauge, 3.8-mm (0.15-in.) steel and has welded-on reinforcement at the bottom edge for extra strength and durability.

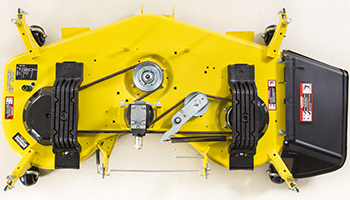

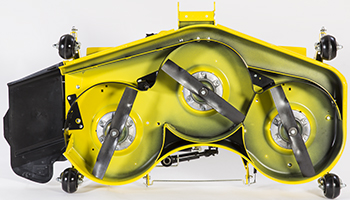

152-cm (60-in.) HC Mower Deck top view

152-cm (60-in.) HC Mower Deck top view

137-cm (54-in.) HC Mower Deck bottom view

137-cm (54-in.) HC Mower Deck bottom view

High-capacity mower decks are formed in a hydraulic press to minimize the number of welds and provide a smooth underside for reduced material buildup:

- Wider and higher discharge opening provides an even clipping dispersal for an excellent finished appearance in all conditions.

- Durable plastic deflector spreads grass clippings evenly across the lawn, is hinged, and can be raised to minimize the storage space required.

- 2.5-cm (1-in.) cold-forged spindles are heat-treated for strength and supported by ball bearings.

- Front edge is raised above the blade plane to allow even cutting of tall grass.

- Blade overlap is greater than many conventional decks for a clean cut.

- Mower can side-discharge, mulch (optional), or use a Power Flow™ collection system (optional).

Tire-grab feature and shark tooth shaped grips

Tire-grab feature and shark tooth shaped grips

Drive-over ramp removed for spindle access

Drive-over ramp removed for spindle access

Ramps are provided to permit driving over the mower deck for installing and removing it from the tractor:

- Constructed of 30 percent glass-filled polypropylene for strength to carry the weight of the tractor

- Polypropylene material will not rust or corrode for lasting good appearance

- Shark tooth shaped grips designed into the ramp inclines for added wheel traction when driving onto the mower deck

- Tire grab at the rear of the ramp gives extra wheel traction

- Ramps removed and replaced without tools to permit convenient servicing of the mower spindles

Mower wash port

Mower wash port

Mower wash port with hose connector

Mower wash port with hose connector

A wash port is provided to make cleaning the underside of the mower deck easy:

- Hose connector is included with the mower deck.

Optional high-performance mulching attachment

Mulching attachment components (48 HC shown)

Mulching attachment components (48 HC shown)

The high-performance mulching attachment provides excellent mulching performance:

- This is a high-performance mulching attachment that includes formed steel baffles to control the material and special mulching blades for superior performance.

- The special mulching blades that are included can also be used for side discharging and collecting, though overall performance may be slightly less than with the standard blades.

- Order: BM23977, 54 HC mulching attachment or BM23978 60 HC mulching attachment

Optional MulchControl™ attachment

Optional AutoConnect™ drive (BM25677)

X758 Tractor driving onto high-capacity mower deck

X758 Tractor driving onto high-capacity mower deck

AutoConnect option installed on X758 Tractor

AutoConnect option installed on X758 Tractor

The AutoConnect driveshaft is an optional kit that will automatically connect or remove the drive from the mower deck to the tractor’s mid power take-off (PTO) shaft.

The AutoConnect drive does not need to be removed from the tractor when using front-powered equipment.

MulchControl with baffle closed

MulchControl with baffle closed

MulchControl with baffle open

MulchControl with baffle open

The MulchControl attachment makes mulching more practical for many mowing situations because it not only does an excellent job of mulching but it also allows the mower to be easily converted for times when it is more desirable to side discharge or collect the lawn material. Advantages of mulching grass clippings include:

- A beautiful looking lawn

- Grass clippings not blown onto the operator, driveways, or flower beds

- Less fertilizer use

- Elimination of the effort needed to dispose of clippings

MulchControl is an innovative, simple design that is easy to use and maintain:

- The MulchControl attachment includes baffles to control the flow of material under the deck.

- The left mower blade area is completely enclosed and optimized for mulching, thus will mulch even when the mower is in the side-discharge mode.

- Baffles around the center and right blades are optimized for mulching when the discharge baffle is closed.

MulchControl operation

MulchControl handle (standard with MulchControl)

MulchControl handle (standard with MulchControl)

Hydraulic MulchControl actuator option

Hydraulic MulchControl actuator option

The optional MulchControl attachment comes with a handle on top of the mower deck that is used to open and close the discharge baffle:

- The operator is required to get off the machine in order to engage or disengage mulch mode.

An optional hydraulic MulchControl actuator attachment is available to replace the standard control lever and allow the operator to control MulchControl from the seat using the tractor’s hydraulic control lever.

NOTE: To have hydraulic control of the MulchControl baffle, both MulchControl and hydraulic MulchControl actuator attachments must be ordered. The hydraulic MulchControl actuator is an extra-cost option for the MulchControl attachment.

Changing from mulching to side discharge or vice versa with the hand lever or hydraulic MulchControl actuator option takes only a few seconds.

MulchControl is well-suited to the following mowing situations:

- Usually mulch, but side discharge when grass gets too long

- Usually side discharge, but would like to be able to close the chute to control clippings

- Always mulch a main lawn, but often side discharge secondary lawns

- Bag clippings, but want to go farther before emptying bags

MulchControl puts the operator in control of the clippings. Now the operator can have all the benefits of mulching with the ability to easily change to side-discharge or bagging when needed.

MulchControl limitations

While in the side-discharge mode, MulchControl will still mulch about one-third of the material. Therefore, the side-discharge mode is essentially a partial-mulch mode. This can be an advantage when side discharging or bagging, as it helps to reduce the amount of material being discharged. Other times this could work as a disadvantage:

- When cutting strong southern grasses, such as Zoysia and Bermuda

- When cutting in wet, high-growth conditions, such as those found in the Pacific Northwest United States

- When optimum bagging and lawn clean-up is desired

MulchControl compatibility

MulchControl is a field-installed attachment. Mulching blades are included:

- MulchControl is for 2015 and newer X700 Signature Series Tractor and:

- 9074M 137-cm (54-in.) HC Mower Deck (serial number 030,001-070,000)

- 9078M 137-cm (54-in.) HC Mower Deck (serial number 070,001-)

- 9075M 152-cm (60-in.) HC Mower Deck (serial number 030,001-070,000)

- 9079M 152-cm (60-in.) HC Mower Deck (serial number 070,001-)

- Optional hydraulic MulchControl actuator (BUC10536) is available for model year 2019 and newer mower decks (9078M and 9079M) only. In addition, mower must be equipped with the basic MulchControl attachment.

NOTE: The hydraulic MulchControl actuator is not available for the 122-cm (48-in.) Accel Deep™ Mower Deck.

Order:

BM26300 MulchControl attachment (54 HC)

BM25258 MulchControl attachment (60 HC)

BUC10536 Hydraulic MulchControl actuator

Mower deck attachability

X758 Tractor driving onto high-capacity mower deck

X758 Tractor driving onto high-capacity mower deck

High-capacity mower decks have ramps positioned on top of the deck for easy installation:

- On a four-wheel drive (4WD) tractor, the operator can simply drive onto and over the deck.

- On a two-wheel drive (2WD) tractor, the operator must back onto and over the deck.

To remove the mower deck:

- Disconnect the drive shaft.

- Unlock the draft arm locks.

- Back or drive the tractor onto and off the mower deck.

- On a 4WD tractor, the operator can simply back onto and off the deck.

- On a 2WD tractor, the operator can simply drive forward onto and off the deck.

Drive-over mower quick reference (major steps)

John Deere has designed a system that makes it easy to remove and reinstall the mower deck. A few steps need to be followed carefully to ensure success.

The list below includes the major steps. Refer to the operator’s manual for a more detailed procedure. The tractor most likely has the mower already installed, so these steps begin with the removal procedure.

DRIVEJD – Always Dependable Product

Mower removal steps

Drive tractor to level area.

Ready mower deck.

- Adjust wheels and lower mower deck

- Draft arms removed (front) and released (rear)

- Power take-off (PTO): disconnect if manual PTO-connect system, then back up to clear rear draft arms (if equipped with AutoConnect™, backing up also disconnects the PTO)

- Raise rear draft arms

Increase engine speed, engage traction assist, and drive over.

Mower installation steps

Verify tractor and mower are ready.

- Alignment of tractor and mower deck

- Draft arms up

- PTO in correct position (If manual PTO connect, place shaft in mower hanger)

Engage traction assist, increase engine speed, and drive or back over.

Join mower to tractor.

- Alignment and attachment verified and PTO connected

- Draft arms hookup, front

- Position mower wheels

Done! Set mower deck height and mow.

An exclusive 4-year or 700-hour (whichever comes first), single-source, bumper-to-bumper warranty* is standard for all John Deere X700 Series Tractors.

- The warranty is hassle free, with one company handling all the paperwork.

- Premium features of X700 Series Tractors allow for this longer warranty period, with more coverage than comparable tractors.

*Term limited to years or hours used, whichever comes first, and varies by model. See Agriculture and Turf equipment Warranty Statement.at JohnDeere.com.au for details.

Twin Touch foot control

Twin Touch foot control

Cruise control

Cruise control

Twin Touch foot pedals control the speed and direction of travel:

- Automotive-type accelerator control for easy operation

- Twin Touch design that allows operator to change direction without lifting foot off platform

- Large pedal surface for increased operator comfort

When the master brake pedal is depressed, the power take-off (PTO) and cruise control disengage.

Cruise control is standard equipment:

- To engage, push in on the cruise lever and hold until the foot is removed from the forward pedal.

- For emergency stop, the cruise control can be released by pushing on the master brake pedal or pushing down on the forward pedal.

Heavy-duty two-wheel steer or four-wheel steer transaxle

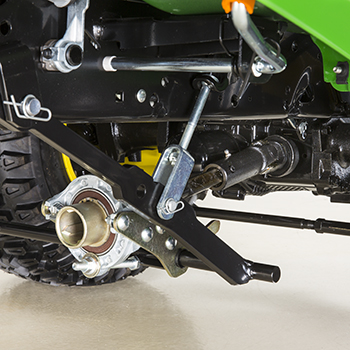

X739 four-wheel steer transaxle

X739 four-wheel steer transaxle

A rugged, heavy-duty commercial hydrostatic transaxle handles a wide variety of ground-engaging applications and commercial mowing usage. A hitch for tow-behind equipment is included. The tractor frame extends behind the transaxle to provide mounting points for the category 1 3-point hitch and Click-N-Go™ mounting brackets.

Many quality features are provided:

- Universal joint splined drive shaft between the engine and transmission is durable and gives efficient power transfer (no belts, no slippage, no power loss).

- Shaft drive output through continuous live transmission PTO has no belts to slip or wear out.

- Internal hydraulic PTO with multi-disk clutch pack:

- Soft, smooth clutch engagement

- Long disk life with continuous oil bath

- No service required, as disks are self-adjusting

- Internal, wet-disk brakes:

- Isolated from dirt, rust, ice, or other contaminants for effective brake operation

- Constantly cooled by transmission fluid to minimize wear and eliminate loss of brakes from overheating

- Quiet design virtually eliminates hydrostatic whine.

- Large, efficient 8-cc charge pump produces excellent flow and pressure to allow operating a variety of hydraulic powered equipment.

- Externally mounted, oil-filled shock absorber in the transmission control system ensures smooth starts and stops.

- Exceptional strength and durability:

- Automotive-type forged flanged axles

- Cast-iron axle housings

- Uses an axial piston-type hydrostatic pump and motor versus less-efficient ball-type rotating groups

Two-wheel steer hydrostatic transaxle

Two-wheel steer hydrostatic transaxle

Four-wheel steer hydrostatic transaxle

Four-wheel steer hydrostatic transaxle

Two-wheel drive (2WD) and 4WD tractors use similar transaxles, however, four-wheel steer tractors have additional features that allow the rear wheels to turn.

Differential lock control

Differential lock control

Infinite control of ground speed and smooth change of direction provide efficiency and operator convenience. The differential lock provides positive power to both drive wheels for increased traction. It can be engaged by the operator as needed.

| Forward | 0 to 8.5 mph (0 to 13.7 km/h) |

| Reverse | 0 to 6 mph (0 to 9.7 km/h) |

Transmission oil cooler

The transmission oil cooler is standard equipment:

- Helps keep oil temperatures cooler during high draft load operations

- Separate automotive-style cooler that provides increased capacity for the oil cooler as well as the radiator, when compared to an oil cooler internal to the radiator

Full-time 4WD for superior traction

X739 Tractor mowing

X739 Tractor mowing

Full-time 4WD front axle

Full-time 4WD front axle

The full-time 4WD front axle provides a superior combination of traction and maneuverability. When the tractor is in a turn, the front wheels need to rotate faster because of the larger arc, compared to the rear wheels, they are traveling in. The hydrostatic front-wheel motors automatically increase the average travel speed of the front wheels when the tractor is in a turn.

The full-time 4WD system optimizes steering performance to provide maneuverability and trimming ability comparable to that of 2WD models, turning radius of 25 in. (63.5 cm) for two-wheel steer models and 21 in. (53.3 cm) for four- wheel steer models, with the added benefit of four-wheel traction.

Full-time 4WD front-wheel motors are powered by the same pressurized hydraulic fluid that powers the rear transaxle drive motor:

- Hydraulic lines move the pressurized fluid from the rear axle to the front-wheel drive motors, located near the center of the front axle, after the oil has passed through the rear transaxle drive motor.

- The two front wheel motors receive fluid in parallel so each gets the amount of fluid needed to enable different speeds during turns, similar to a differential assembly, and allow smooth turns.

- Turning radius of tractors with full-time 4WD is the same as for 2WD models, and considerably less than the turning radius for tractors with mechanical 4WD.

- Full-time 4WD functions in forward and reverse.

Control arm increases front-wheel speed in turns

Control arm increases front-wheel speed in turns

Front-wheel drop-axle

Front-wheel drop-axle

- A control rod (looks similar to a steering drag link) adjusts the swash plate of the variable-speed wheel motors, so each wheel motor is operated at the optimum speed during turns to minimize tire scuffing and assist in making tight turns.

- Front-wheel drop-axles provide extra-tight steering capability, improved ground clearance, and include speed-reduction gearing.